64V40WH-变电站DC-DC变换装置

超级电容模组 V1.00

超级电容产品事业部

Supercapacitor Product Division

产 品 规 格 书

Product specification

Customer 客户名称:

Product 产品名称: 模组型锂离子超级电容

Description 规格/型号: PLM64V40WHT

Date 日 期: 2024年 04 月 01 日

Version No. 版 本 号: V1.00

|

Prepared 制作 |

Checked 审核 |

approval 批准 |

|

|

|

|

|

Customer Approve 客户承认 |

||

|

|

||

超级电容模组 V1.00

目 录 Index

2.标准测试条件 Standard test condition: 3

3.基本性能范围 Basic performance range: 4

4.产品外形图、尺寸 Product shape and size: 6

5.产品端子定义 Product Terminal Definition: 6

7.包装、运输、储存 Packaging, transportation, storage 10

超级电容模组 V1.00

本规格书规定了SLM64V40WHTDB 锂离子电容器模组性能、测试方法, 进行技术规范 化,作为技术确认依据。

2.标准测试条件 Standard test condition:

一般情况下,在标准大气压下,温度 15~35℃,湿度≦85%RH,大气压 86Kpa~106Kpa 条件下 进行测试;测试前样品应该在常温下放置 12H 以上。

如对结果有疑问时,应按照温度为 25±2℃,湿度:60~70%RH ,标准大气压 86Kpa~106Kpa 条件测量。

3.依据规范 According to the specification:

IEC 62813:2015《电气和电子设备用锂离子电容器电气特性试验方法》

IEC 62931-1《电子设备用固定电双层电容器。第 1 部分通用规范》

IEC 62931-2《电子设备用固定电双层电容器。第 2 部分通用规范》

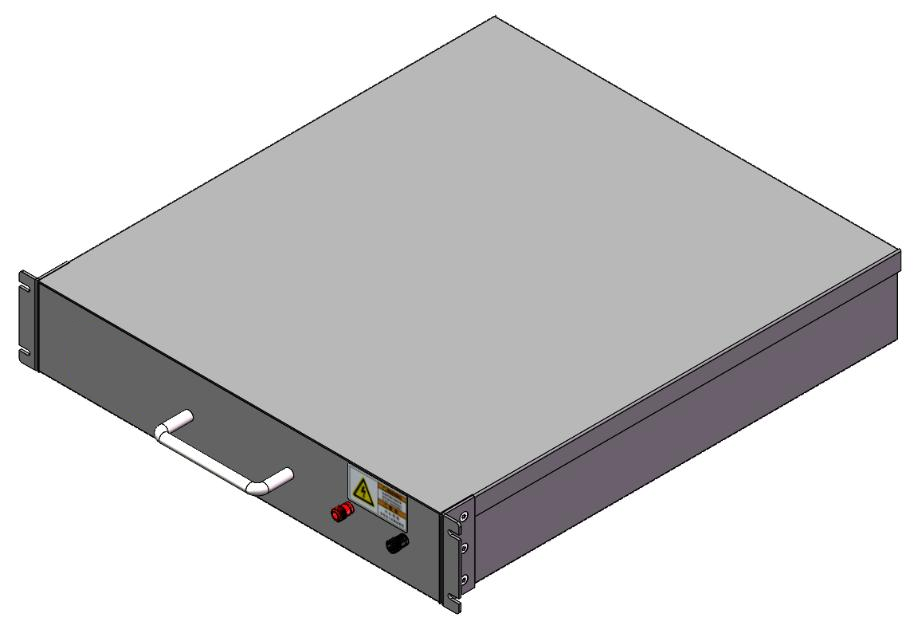

4. 产品外形图、尺寸 Product shape and size:

5. 产品端子定义 Product Terminal Definition:

6. 测试方法 Testing Methods:

6.1 容量测试电路原理 Principle of capacity test circuit

图1 恒流放电方法电路Constant current method circuit

河南品越电子科技有限公司

张工 15538577277 第 6 页 共 13 页

超级电容模组 V1.00

6.2 容量测量方法 Capacity measurement method

6.2 容量测量方法 Capacity measurement method

——恒流/恒压源的直流电压设定为额定电压(UR)The DC voltage of the constant current/constant voltage source is set to the rated voltage;

——设定恒电流放电装置的恒定电流值 ISet the constant current value I of the constant current discharge device;

——将开关 S 切换到直流电源,电容器恒流充电到额定电压并恒压 30min 后转换为恒流放电 Switch S to the DC power supply, the capacitor is charged to the rated voltage at constant current and then converted to constant current after 30min of constant voltage。

图2 电容量测试示意图 Schematic diagram of capacitance test

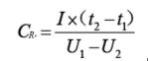

测量电容器两端电压从 U1 到 U2 的时间 t1 和 t2 ,如图 2 所示,根据下列等式计算电容量值 Measure the time T1 and T2 of the voltage from U1 to U2 at both ends of the capacitor, as shown in FIG. 2. Calculate the capacitance value according to the following equation::

式中 Type in the:

CR——容量(F)capacity;

I——放电电流 1C(mA));Discharge Current 1C(mA);

U1——测量初始电压 U1=3.8*N(V);Voltage before test:U1=3.8*N(V); U2 ——测量终止电压 U2=2.7*N(V);Voltage after test:U2=2.7*N(V);

t1——放电初始到达 U1( s ) 电压的时间 Time between initial discharge and voltage reaching U1(s); t2——放电初始到达 U2( s ) 电压的时间 Time from initial discharge to voltage reaching U2(s)。

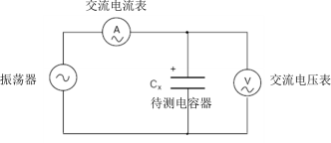

6.3 交流内阻 AC ESR

6.3.1测试电路原理Principle of test circuit

超级电容模组 V1.00

图3 交流阻抗电路 AC impedance circuit

6.3.2测量方法Method of measurement

电容器的交流内阻 ESRAC 应通过下式计算 The AC internal resistance ESRAC of the capacitor shall be calculated as follows:

![]()

式中 Type in the:

ESRAC——交流内阻(Ω) Ac internal resistance;

U——交流电压有效值(V)Effective value of AC voltage; I——交流电流有效值(A)Effective value of AC current;

测量电压的频率应为 1kHzThe voltageshall be measuredata frequency of 1kHz; 交流电流应为 1mA 至 10mAAc current should be 1mAto 10mA。

6.4 直流内阻

6.4.1测试方法Method of measurement

——恒流/恒压源的直流电压设定为额定电压( UR )The DC voltage of the constant current/constant voltage source is set to the rated voltage;

——设定恒电流放电装置的恒定电流值 I Set the constant current value I of the constant current discharge device;

——将开关 S 切换到直流电源,电容器恒流充电到额定电压并恒压 30min 后转换为恒流放电 Switch S to DC power supply, capacitor constant current charge to rated voltage and constant voltage 30min after conversion to constant current current;;

——用电压记录仪记录电容器充放电转换端电压瞬间 10ms 电压降的变化量 ΔU3,如图 2 所示 A voltage recorder was used to record the change of 10ms voltage drop ΔU3 at the transient voltage of the charging and discharging terminal of the capacitor, as shown in Figure 2。

根据下式计算直流内阻 ESRDC Calculate the DC internal resistance according to the following equation:

![]()

式中 Type in the:

ESRDC——直流内阻(Ω) The dc resistance;

超级电容模组 V1.00

ΔU3——10ms 电压降(V)10 ms voltage drop;

ΔU3——10ms 电压降(V)10 ms voltage drop;

I ——放电电流 1C(mA));Discharge Current 1C(mA)。

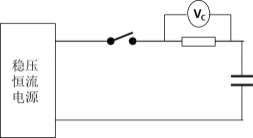

6.5 漏电流 Leakage current

——测量之前待测锂离子电容器应充分开路静置,一般静置 12h 以上 Before measurement, the lithium ion capacitor to be measured shall be fully open-circuit and allowed to stand for more than 12h;

——恒流/恒压源的直流电压设定为额定电压( UR )Constant current/constant voltage source DC voltage set to rated voltage (UR);

——选择合适的保护电阻 RS,经过最大 30min 充电时间后达到 95%充电电压 The appropriate protection resistance RS is selected to reach 95% charging voltage after the maximum charging time of 30min;

——用电压表记录 72h 后保护电阻两端的电压 US ,如图 4 所示 Use a voltmeter to record the voltage (US) at both ends of the protection resistance after 72h, as shown in figure 4;

——漏电流 LC 值即为 US/RS 的比值 LC value of leakage current is the ratio of US/RS。

图4 漏电流测试电路图Leakage current test circuit diagram 有关相应标准规定Relevant relevant standard provisions

——测试参考温度为20℃,在其他温度测量时应有相关修正系数The reference temperature of the test is 20℃.When measuring other temperatures, there should be relevant correction coefficient; ——规定充电时间 Set charging time;

——高精度的稳压电源 High precision regulated power supply; ——高精密的保护电阻 High precision protection resistor。

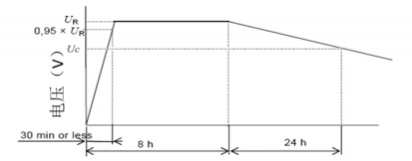

6.6 自放电

——测量之前待测锂离子电容器应充分开路静置,一般静置 12h 以上 Before measurement, the lithium ion capacitor to be measured shall be fully open-circuit and allowed to stand for more than 12h;

——恒流/恒压源的直流电压设定为额定电压( UR )The DC voltage of the constant current/constant voltage source is set to the rated voltage( UR );

——设定规定的恒电流放电装置的恒定电流值 Set the constant current value of the specified constant current discharge device;

——将开关 S 切换到直流电源进行恒流充电,经过最大 30min 充电时间后达到 95%充电电压 Switch S to DC power supply for constant current charging, and 95% charging voltage will be reached after the maximum

超级电容模组 V1.00

charging time of 30min;

charging time of 30min;

——在恒流/恒压源达到额定电压后恒压充电 8hCharge at constant voltage for 8h after the constant current/constant voltage source reaches the rated voltage;

——在恒压充电 8h 结束后,将电容器两端从电压源断开,置于标准条件下 24h 后,测量电容器两端的残 留电压 Uc,如图 5 所示 At the end of 8h of constant voltage charging, both ends of the capacitor are disconnected from the voltage source, and the residual voltage Uc at both ends of the capacitor is measured after 24h under standard conditions, as shown in Figure 5。

图5 自放电测试曲线图Self-discharge test curve

7.包装、运输、储存 Packaging, transportation, storage

c、请勿放在可燃物附近。否则有引起火灾的危险 Do not place near combustibles. Otherwise there is a risk of fire.

d、谨防杂物进入模组内部。否则有引起设备故障的危险 Beware of debris entering the module. Otherwise, the device may fail.

8.3 搬运和移动时的注意事项 Precautions for handling and moving

8.4 运转操作时的注意事项 Points for attention during operation

8.5 维护检查时的注意事项 Precautions for maintenance checks